January 23, 2020 No Comments

Table Conversion Increases Throughput by 40%

Tennessee, USA

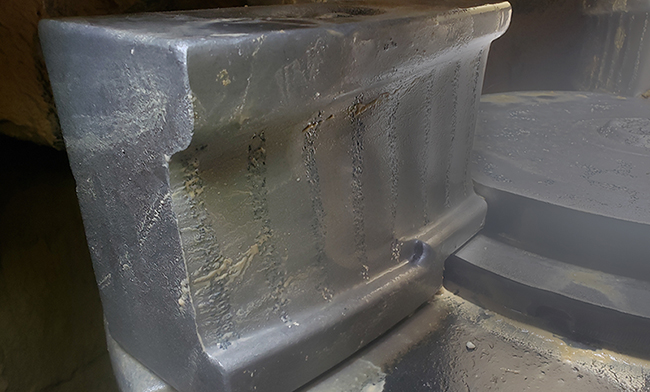

Sandstone Crusher

“Recirculation rate reduced from 25% to 12.5%, a 50% improvement.”

Spokane Model 66

Baseline:

- 3 port rotor running at 1575 RPM with Spokane anvil ring

- 100 tons per hour input. Material backed up in rotor causing frequent production interruptions

- Output of 75 tons per hour

- Recirculation rate of 25%

Objective:

- Installation of Spokane Industries 5 shoe table fitted with Si-Tec® ceramic shoes

- Increase machine throughput

Reduce table RPM - Reduce recirculation

Results:

- 20% increase in input (100 to 120 Tons/Hour)

- 50% Reduction in recirculation rate (25% to 12.5%)

Value delivered:

- 40% Increase in throughput (75 to 105 tons/hour)

- Table speed reduced to 1150 RPM, reducing wear cost, energy costs, and machine maintenance